CORE COMPETENCY Core Competency

.png)

Extensive R&D Design Capabilities and Experience

Transworld Steel leverages its extensive experience to expertly address and meet a broad spectrum of customer needs. This deep expertise allows us to tackle even the most specific and challenging requirements with unparalleled precision and reliability, ensuring exceptional satisfaction across all client demands.

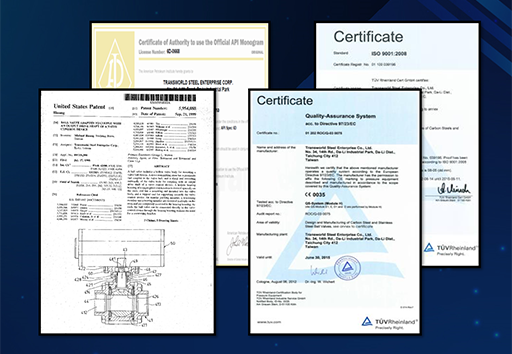

Holding a Portfolio of Patented Technologies

Driven by a commitment to innovation, we actively develop cutting-edge products and leverage our strong research and development capabilities. Our efforts are reflected in the 50 patents we hold, showcasing our dedication to advancing technology.

Lab Overview

- Pressure Testing: API 598 / EN 12266-1

- Fire Safe Testing: API 607 / ISO 10497

- Fugitive Emission Testing: TA Luft / ISO 15848

-

Torque Testing: Under ambient conditions, pressurized conditions and elevated temperatures

-

Cycle Testing: Stem endurance, seat durability, lifecycle performance under high temperature and pressure

- PTFE Seat Life Testing Unit

- Temperature:Ambient

- Pressure:N/A

- Medium:N/A

- Temperature Testing: Temperature +500℃ / -50℃ / -196℃

- High Temperature Vaccum Testing Equipment

- Temperature:500℃

- Pressure:Vacuum 3x10-3torr 1500psi Max.

- Medium:Nitrogen

- -60℃ Cryogenic Freezer

- Temperature:-60℃

- Pressure:2900 psi Max.

- Medium:Nitrogen

- Ultra-Low Temperature Testing Equipment

- Temperature:Liquid nitrogen -196℃

- Pressure:2000 psi Max.

- Medium:Helium

Professional Removal of Hazard Particles

In the manufacturing process of sanitary products, particles in the air can adhere to the products, reducing their quality and even affecting the original design functionality. Therefore, it is crucial to enhance the safety and hygiene of the environment by using sanitary clean rooms.

The primary objectives are to prevent contamination of pharmaceutical equipment, ensure proper cleaning and maintenance, and improve dust control systems. There is also a risk of cross-contamination with steroids, cytotoxins, or hormones. Therefore, controlling the number of particles and biological microorganisms in the manufacturing environment is crucial.

Types of Valves That Can Be Produced in Clean Rooms

Sanitary Ball Valve

Pharmaceutical Ball Valve

Oxygen Service Valve

Gas Valve

Electropolishing

Electropolishing is a surface treatment process that not only enhances the appearance of castings, making them more visually appealing, but also removes surface contaminants. This process improves light reflection, enhances the shine, and increases the corrosion resistance of the castings.

Sanitary Valve Inspection

In addition to basic measuring tools such as calipers, torque wrenches, 3D measurement devices, and pressure testing equipment, Transworld Steel also uses surface roughness gauges and ferrite content detectors to ensure the quality of sanitary valves. This guarantees that all valves and products meet high-quality standards upon shipment.

During shipping, standard cartons are used for packaging. Sanitary valves are additionally wrapped in plastic bags and sealed to protect them from contamination during transport.

Clean Dry Air System

Ultrapure Water System

Clean Room Level Specifications

- PIC/S GMP = EU GMP Systematics Standard

- FED-STD-209E Class 100 / Class 10K

- ISO 14644-1 Class ISO 5 ~ Class ISO 7

Sophisticated Experience in Metal Machining

Transworld Steel utilizes advanced, high-capacity CNC machines known for their stability, along with precision automated measurement systems. Our extensive experience and expertise enable us to effectively meet a wide range of customer needs. By incorporating automation systems and robotic programming, we significantly enhance production efficiency, reduce machine adjustment time, lower labor costs, and save on capital expenditures.

Achieving Labor Efficiency

In today's labor-scarce environment, the metalworking industry faces growing demands for skilled personnel and exceptional talent. Additionally, customer expectations and product standards are more rigorous than ever before. To address these challenges, many machine manufacturers are offering solutions to bridge labor gaps and satisfy client needs. At Transworld Steel, we have developed a tailored solution by integrating Universal Robots™ with CNC lathes. This approach delivers significant labor savings and ensures consistent workpiece quality, effectively bridging the gap between workforce demands and operational needs.

Seamless Integration of UR Robots

Our technicians seamlessly integrate UR collaborative robots into our operations, with no need for additional safety measures. This innovative "colleague" from Denmark is exceptionally easy to set up. Once unboxed and powered on, we swiftly began operations. Our team quickly learned to program the UR robots, completing the initial modular programming in just 4 hours. Within 7 hours, the UR collaborative robot was fully operational, offering rapid setup, minimal training requirements, and high safety.

Machining Equipment with IoT Integration

- Smart Monitoring Rate

- 85%

- CNC Machines

- 35+

- Robotic Arm

- 7+