Intelligent Valve Monitor

Industrial plant’s pipeline has long lacked clear feedback on valve status, putting plant at potential risks and unexpected operational halts. IVM addressed this issue by continu-ously monitoring valve status and provide crit-ical valve information.

DownloadProduct Features

Emission Detection

Continuously detects emissions in real time, allowing immediate response to contain leaks, minimize risk, and maintain system integrity.

LED Indicator

The LED light indicates valve statuses with seven customizable colors, facilitating quick identification and signaling issues to prevent incidents.

Valve Torque

Torque monitoring informs maintenance based on real valve wear, therefore enhancing longevity and reducing unexpected downtime.

Traceability

The integration with Transworld's Digital Traceability Passport (DTP) ensures accountable operations, aiding in troubleshooting and enhancing maintenance reliability.

Cycle Counter

The cycle counter records the number of valve open/close actions, supplying data to inform proactive maintenance and enhance system safety.

Valve Position

The sensor precisely measures valve angles to 360°, ensuring accurate closure and leakage prevention, and also identifies on/off positions.

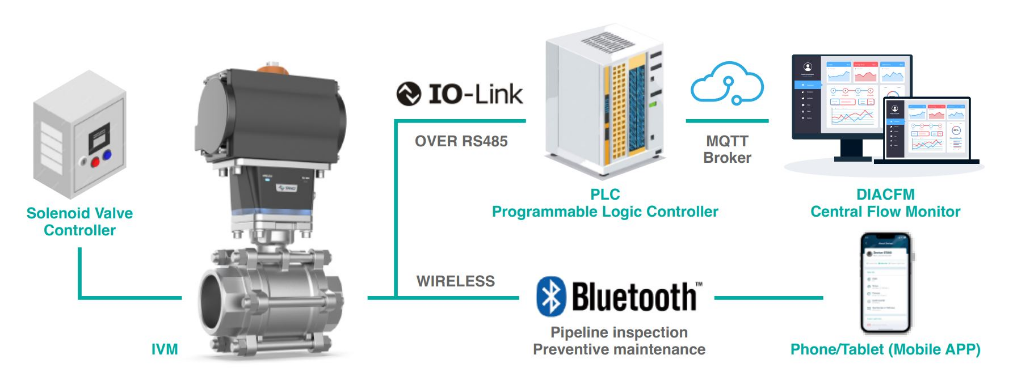

Integration with Modern Technologies

This system facilitates the seamless incorporation of the latest technological breakthroughs, opening avenues for further innovations and improvements. It facilitates the adoption of smart technologies, offering a platform that is ready for the future and can adapt to evolving technological landscapes. In the modernized setup facilitated by the IVM, operators are relieved from the necessity of using limit switches and intricate sensor wiring. This significant shift brings forth a range of substantial benefits, fostering an environment of improved safety and streamlined operations, as detailed to the right.

We offer MQTT to customers to facilitate the creation of an enterprise management situation room to elevate the factory’s security.